- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Size: 10-10000

- Place of Origin: jinan china

- Brand Name: Jinan Zhengmai Mechanical Equipment Co.,Ltd

- Model Number: ZM-1000L

- Weight: 999.000 kg

Before introduction of the mashing system , I wanner to show thewholebeer brewery project process , from the Brewhouse System ,FermentationSystem ,Beer Serving System , Micro Beer Selling Systemincluding theauxiliary device .Through this drawing , you will brieflyunderstand thedraft beer brewery process.Zhengmai Economic turnkey beerbrewery systemcan brew different tastes of the beer according to thedifferent market requirements.

Brewhouse for two tanks enables wort production . mash mixing , Lautering , boiling and kettle function , mashing and lauter are performed in kettlewith steam heating system , lautering is gravitational , Whirlpool tank also can be the boiling tank with steam heating function , control panel isa part of the brewhouse , in the brewhouse there is mash pump , wort and hot water pumps and stainless steel one level plate wort cooler .

Brewhouse consists of two vessels creating one unit together with platform , staircase ,control panel , hot liquor tank , piping and plate wort cooler .Kettle ( the left tank ) has the following functions : mash mixing ,mashig and lautering , it is mashing and to separate the wort from grains ,the boilikng / Whirlpool tank ( the left tank ) can be as the whirlpool and boiling function . The brewhouse can brew the beer 3 time maximumly , which can save the time .

Heating of two brewhouse tanks is provided by steam through side and bottom , the hot water abstracted from the wort coller can be transfered tothe hot water tank and also can be as the lauter spraying water to save the energy . Wort cooling is done in stainless steel one level palte coolerwhich is a part of the brewhouse .

The main features for our system

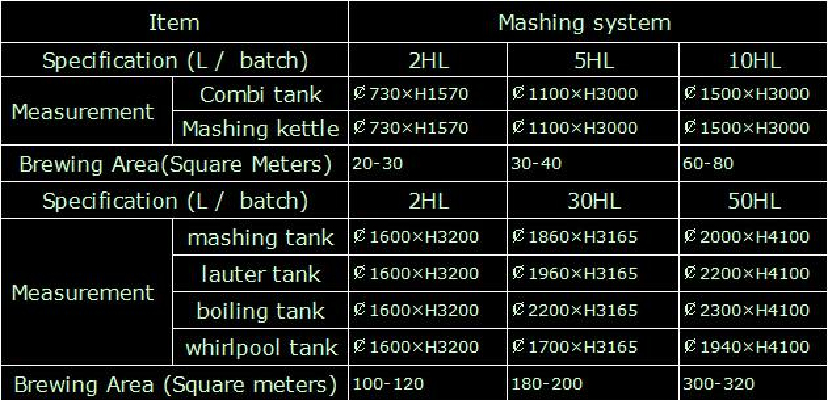

1.Mashing system : it is the semi-automatic machine with seperated power controller which is fixed near to this sytem to be convenient to operate it , the heating process is automatic with 5 phase programmes inside ; this brewhouse can brew 2-3 times per day , the hot water absorbed from the wort heat exchanger can be reused to save the energy.

2. Fermentation system : Automaticly cooling system with whole stainless steel cooling pipeline which will be more durable during the operation , the cooling jacket adopts dimple welding with better cooling function , the chiller compressor with Copland brand .

3. The material adopts stainless steel Korea Pohang Brand , the polish can be 0.4UM with professional polishing machine .The welding adopts arc argon protection welding witihout any leakage with 48 hours pressure and water testing .

4. The optional elements : we can also offer Siemens / ABB motor and pump , Danfoss speed frequency device , Belimo Solenoid , Wilo ice water pump and CIP pump ,Schneider electric elements inside of the power cabinet with international repair function .

5. We can also offer installation & dubugging service , also you can make the installation according to our CAD and 3D drawing , since all the pipeline adoptsstainless steel SUS304 pipeline with ferrule connections . Our installation is quick and easy to operate .

6. We can also arrange the shippment from China to Canada with containers , all the products will be packed for safe sea shippment .

7. Our quality gaurangee for the tank is 3 years , 1 year for the electric elements , during this time we will change all the destroied elements for free , we also match the enough auxiliary fittings for you .

- Size: 10-10000

- Place of Origin: jinan china

- Brand Name: Jinan Zhengmai Mechanical Equipment Co.,Ltd

- Model Number: ZM-1000L

- Weight: 999.000 kg

Before introduction of the mashing system , I wanner to show thewholebeer brewery project process , from the Brewhouse System ,FermentationSystem ,Beer Serving System , Micro Beer Selling Systemincluding theauxiliary device .Through this drawing , you will brieflyunderstand thedraft beer brewery process.Zhengmai Economic turnkey beerbrewery systemcan brew different tastes of the beer according to thedifferent market requirements.

Brewhouse for two tanks enables wort production . mash mixing , Lautering , boiling and kettle function , mashing and lauter are performed in kettlewith steam heating system , lautering is gravitational , Whirlpool tank also can be the boiling tank with steam heating function , control panel isa part of the brewhouse , in the brewhouse there is mash pump , wort and hot water pumps and stainless steel one level plate wort cooler .

Brewhouse consists of two vessels creating one unit together with platform , staircase ,control panel , hot liquor tank , piping and plate wort cooler .Kettle ( the left tank ) has the following functions : mash mixing ,mashig and lautering , it is mashing and to separate the wort from grains ,the boilikng / Whirlpool tank ( the left tank ) can be as the whirlpool and boiling function . The brewhouse can brew the beer 3 time maximumly , which can save the time .

Heating of two brewhouse tanks is provided by steam through side and bottom , the hot water abstracted from the wort coller can be transfered tothe hot water tank and also can be as the lauter spraying water to save the energy . Wort cooling is done in stainless steel one level palte coolerwhich is a part of the brewhouse .

The main features for our system

1.Mashing system : it is the semi-automatic machine with seperated power controller which is fixed near to this sytem to be convenient to operate it , the heating process is automatic with 5 phase programmes inside ; this brewhouse can brew 2-3 times per day , the hot water absorbed from the wort heat exchanger can be reused to save the energy.

2. Fermentation system : Automaticly cooling system with whole stainless steel cooling pipeline which will be more durable during the operation , the cooling jacket adopts dimple welding with better cooling function , the chiller compressor with Copland brand .

3. The material adopts stainless steel Korea Pohang Brand , the polish can be 0.4UM with professional polishing machine .The welding adopts arc argon protection welding witihout any leakage with 48 hours pressure and water testing .

4. The optional elements : we can also offer Siemens / ABB motor and pump , Danfoss speed frequency device , Belimo Solenoid , Wilo ice water pump and CIP pump ,Schneider electric elements inside of the power cabinet with international repair function .

5. We can also offer installation & dubugging service , also you can make the installation according to our CAD and 3D drawing , since all the pipeline adoptsstainless steel SUS304 pipeline with ferrule connections . Our installation is quick and easy to operate .

6. We can also arrange the shippment from China to Canada with containers , all the products will be packed for safe sea shippment .

7. Our quality gaurangee for the tank is 3 years , 1 year for the electric elements , during this time we will change all the destroied elements for free , we also match the enough auxiliary fittings for you .